D-SIMLAB

Simulation support for semicon and aerospace

In Singapore, Gan Boon Ping has been involved in simulation technology application and development since 1995. Today, as CEO and co-founder of D-SIMLAB Technologies, he helps lead the way in high-performance simulation-based decision support to enable both aerospace and semiconductor companies to optimise their performance in a sustainable, economic manner. Boon Ping looks back on their journey from research institute to SME and the recent participation in their first ITEA project, AISSI.

Need for speed

The story of D-SIMLAB began when Boon Ping worked as a researcher for the Singapore Institute of Manufacturing Technology and led a multi-year research project funded by the R&D agency A*STAR. This focused on parallel and distributed simulation because simulation in general needed to run at a much faster speed to become practical for industry. “Of course, there is not much use for just having a simulation run faster without a use-case,” smiles Boon Ping. “So, we found two semiconductor fabrication plants in Singapore - Chartered Semiconductor, now GlobalFoundries, and SSMC, a joint venture of NXP and TSMC - and executed simulation projects for them. This meant applying my skillset in computer science to industrial applications.”

“When a research institute develops technology, you typically hand it over to the customer through IP licensing. But the issue is that simulation is not something straightforward that a company will have the core competency to maintain, build and make successful and useful. So, along with my co-founders Dr Peter Lendermann and Dr Nirupam Julka, we came up with the idea of starting a company.”

Two key elements

By chance, the creation of D-SIMLAB coincided with a paradigm shift in the aerospace industry in which spare parts ownership and inventories were outsourced to third parties instead of being maintained by airlines themselves. The fledging start-up therefore shifted to solutions for optimising inventory allocation across airports around the world. With the difficulties facing aviation due to COVID-19, they are again putting substantial resources into the semiconductor domain. This dual focus is reflected in two solutions: D-SIMSPAIR and D-SIMCON, each of which comprises a suite of advanced, domain-specific decision-support modules for planning and optimisation.

“Speed is a key thing,” remarks Boon Ping. “If you look at our competitors providing similar simulation solutions, their runtime is at least two to three times longer than ours. It usually takes an hour or two to run a simulation forecast, so two or three times longer matters. The second aspect is that if you sell general-purpose solutions, your customer has to build everything from scratch and ensure that the simulation model accurately represents reality, requiring a lot of time and investment. Since our solution is tailor-made, it consolidates a lot of domain knowledge within the software itself. For the customer, it’s about feeding data into the system rather than building the model on their own. Deployment time can be reduced from twelve months to six months and the success probability is much higher. So far, you could say it’s at 100% because all customers continue to use our simulation solution today.”

Perception of value

Despite these successes, limited funding for new ideas is an inherent challenge for SMEs. As a result, D-SIMLAB takes part exclusively in publicly funded projects that allow them to collaborate with potential users. “This helps us manage risk,” Boon Ping explains. “In AISSI, for example, 50% of our costs were paid by the government. That allowed us to do much more than if we funded the entire project on our own. At the same time, if you get the government to fund your research, it usually carries considerable weight when you talk to potential customers. So, it’s not just the dollars and cents that help us; it also gives a perception of value behind what we are doing. That is very important for SMEs.”

If you get the government to fund your project, it gives a perception of value behind what we are doing. That is very important for SMEs.

The knowledge exchange

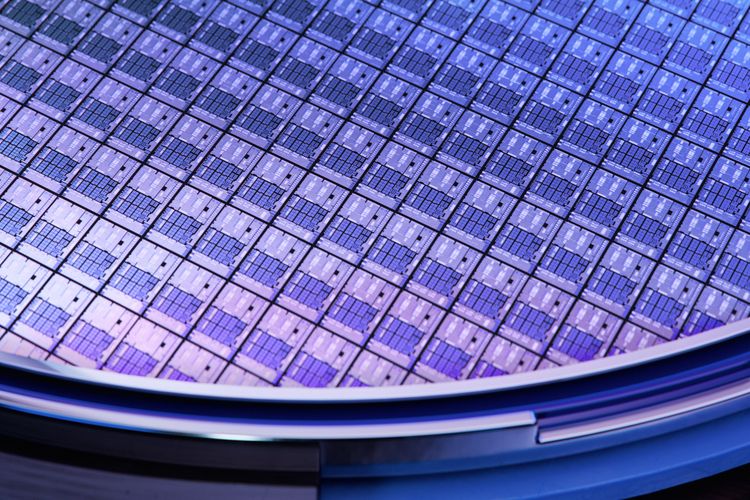

In the ITEA project AISSI – short for ‘Autonomous Integrated Scheduling for Semiconductor Industry’ – D-SIMLAB first dipped their toes into the world of artificial intelligence. Between 2021 and 2024, they worked with German partners Bosch, KIT, Nexperia and SYSTEMA to produce a platform and novel AI-based approaches that optimise semiconductor wafer fab throughput and supply chain predictability. “All partners had their day-to-day jobs besides managing the complexity of interactions and the ideas we were working on. In my view, that was one of the bigger challenges: aligning the interests of all parties to move toward a common goal. I think we were very successful with that.”

The project’s results reflect this achievement. In the semiconductor industry, the trend is moving towards prescriptive analytics to proactively address anticipated issues in the production line, demanding a lot of effort and experience. Through AISSI, D-SIMLAB was able to exchange knowledge with KIT to gain a much deeper understanding of the benefits and risks of using AI for such an approach. “If we want to commercialise any AI-related solution, we have to address the pitfalls to convince customers of the usefulness,” Boon Ping continues. “The AISSI platform helps us open doors to other companies. For example, we can now showcase that our simulation platform works and can integrate with AI for training purposes. With the outcome of this project, we have taken the first step towards using AI.”

Important guidance

Compared to previous experiences with projects in which D-SIMLAB only had contact with one company within a large consortium, Boon Ping considers ITEA’s strong integration of partners to be a major contributor to success for AISSI. “Also, when you have multiple partners working together, things can get messy very quickly if you do not have formal processes to guide and manage things!” he concludes. “With ITEA, there are a lot of formal processes in place, like the review meetings. This is something that I had not seen in other projects. In Singapore, there are no in-between steps where anybody helps steer the direction or helps us understand where we didn’t see clearly. With ITEA, we got a lot of important guidance from the reviews. And the very formal process also ‘forced’ us to be more disciplined in terms of running the project and submitting milestones. So, my experience with ITEA and the AISSI project was very positive.”

More information:

www.d-simlab.com

Other chapters

Use the arrows to view more chapters

Editorial

By Dirk Elias and Régis Cazenave

Country Focus: Canada

Ten years of successful collaborations through ITEA

Kelvin Zero

Taking health data out of silos with Secur-e-Health

ITEA Success story: OPTIMUM

Offering greater efficiency, safety and usability in future smart factories

Community Talk with Erik Rodenbach

Running a well-oiled machine

SME in the Spotlight: D-SIMLAB

Simulation support for semicon and aerospace

End user happiness: Deep4Sat43

Satellite technology enhancing forest health

ITEA PO Days 2024 and exhibition

Active ITEA Community delivers a record number of ideas

ITEA Success story: BIMy

An innovation engine for integrated BIM and GIS