Helsinki, 15 September 2022

OPTIMUM offers greater efficiency, safety and usability in future smart factories

In today’s factories, machines such as cranes are typically operated manually using heterogeneous hardware. These are usually not interoperable and diverse control environments are in use; static machine configurations also make evolution hard to achieve. The ITEA project OPTIMUM enables machines of different kinds and from different manufacturers to communicate with each other and their operators, improving the worker’s and equipment’s safety. In recognition of this exceptional achievement, OPTIMUM received the Special ITEA Award of Excellence today in all three nomination categories: Innovation, Standardisation and Market Impact.

Unique real-time M2M communication

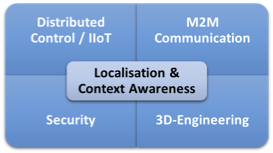

OPTIMUM - gathering 17 partners from Germany, Romania, South Korea, Spain, Turkey and the United Kingdom -

enables real-time M2M and M2H communication, utilising distributed control (DCP), localisation awareness and

3D engineering & visualisation for smart factory applications. This is ground-breaking because previously

only machines from the same manufacturer could communicate with each other at a reasonable cost and

engineering effort.

OPTIMUM - gathering 17 partners from Germany, Romania, South Korea, Spain, Turkey and the United Kingdom -

enables real-time M2M and M2H communication, utilising distributed control (DCP), localisation awareness and

3D engineering & visualisation for smart factory applications. This is ground-breaking because previously

only machines from the same manufacturer could communicate with each other at a reasonable cost and

engineering effort.

Improved safety and reduction in assembly time

For smart manufacturing processes, this communication needs to be realised at an extremely high speed – in

real time – and at an extremely reliant rate. Only then can the safety of operators and equipment be

guaranteed. The basis for this is twofold: firstly, the communication channels need to permit data exchange

with high reliability in real time and, secondly, the system needs to be aware of the current positions of

all of the actors within it – moving or static, human or machine. This way, the system can gain the

necessary context/positioning awareness of all of the actors participating in the material flow.

A great innovation for standard semi-automated applications is the potential for new and cost-efficient assistance functions that revolutionise the efficiency of processes. The outcomes of OPTIMUM are prerequisites for the implementation of smart processes in real Smart Factories in the future.

The consortium has implemented and validated the diverse technical results through demonstrators in 15 use-cases in four countries. Cranes, machines, robots and autonomous driving vehicles were equipped with new assistance functions, like “come to me”, “go-to” and “follow machine”. This will make machines and processes smarter. These innovative assistance functions will significantly reduce assembly times in semi-autonomous processes, where an 18% reduction was already achieved during a Proof of Concept. In real industry applications, even larger efficiency increases are expected. This improves resource utilisation and overall sustainability. Users of the software and applications developed in the OPTIMUM project will have safer and more flexible material handling processes.

With the demonstrators, the consortium has proven the scalability of the results. These demonstrators range from small mobile robots to table-top demonstrators, laboratory demonstrators and real factory applications with demo assembly processes.

Strong standardisation and exploitation results

Three out of eight patent ideas are already registered at a national level, building the grounds for future

market approaches. Remaining patent ideas are under review or in the process of submission.

The development of a globally standardised Open Platform Communication Unified Architecture (OPC UA) data model for cranes and hoists (companion specification) was actively driven by the project partners and evaluated in the OPTIMUM project.

The current successes in market exploitation after the finalisation of the OPTIMUM research project are as follows:

- DEMAG sold a crane to the Fraunhofer Institute for Factory Operation and Automation (IFF) in Magdeburg for its new research factory (Elbfabrik), which will be enabled with innovative assistance functions from OPTIMUM. Consortia partners will support the implementation of the OPTIMUM functionalities.

- NXP is developing an integrated hardware solution based on OPTIMUM results to serve an Evaluation Kit for the industrial market

- TARAKOS has extended their software solutions (taraVRbuilder & taraVRcontrol) and has significantly improved the planning of material handling processes with cranes. The roll-out to the market took place in August 2022 and the extended software is also being sold to the Fraunhofer Institute for the Elbfabrik.

- BEIA has developed its IoT telemetry solution with OPC UA for cranes to be used by NAVROM, the biggest river shipping company in Romania.

- Anja Fischer-Kraus (Demag Cranes & Components GmbH)

This project has received funding from:

Note for editors, not for publication

* The acronym OPTIMUM stands for OPTimised Industrial IoT and Distributed Control Platform for Manufacturing and Material HandlingFor interview requests, questions and additional information about OPTIMUM and ITEA, please contact:

OPTIMUM Contact person

Anja Fischer-Kraus (Demag Cranes & Components GmbH)

anja.fischer-kraus@demagcranes.com

ITEA Contact person

Linda van den Borne-Toupet

linda.van.den.borne@itea4.org

About OPTIMUM

https://itea4.org/project/optimum.html

https://www.linkedin.com/company/optimum-platform

https://twitter.com/optimumplatform

https://www.optimum-itea3.eu

About ITEA

ITEA is the Eureka Cluster for software innovation, enabling a large international community to collaborate

in funded projects that turn innovative ideas into new businesses, jobs, economic growth and benefits for

society. https://itea4.org