ITEA Impact story

AVANTI

Virtual commissioning test methodology gets a competitive edge

Impact highlights

- In all application domains, the project resulted in an efficiency improvement of 25-30 % in production preparation:

- Moventas – windmill gearboxes: significant reduction of the months-long gearbox testing process

- Arcelik – transportation systems for white goods: decreasing the number of stops of trolleys during line commissioning through preceding simulations

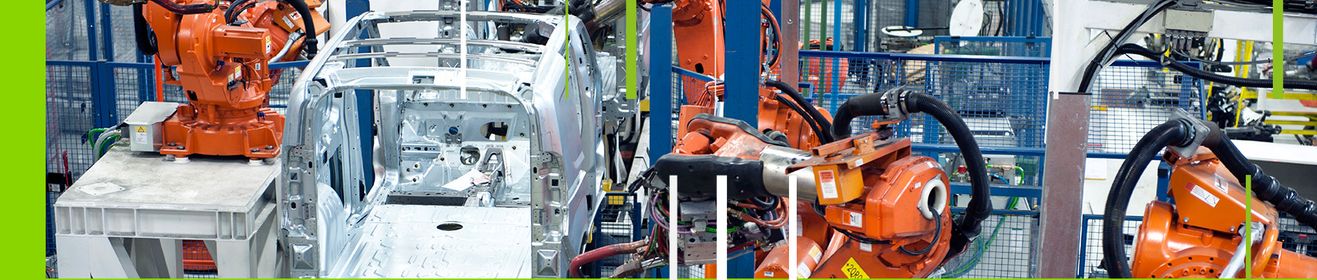

- Daimler – Production equipment for automotive final assembly: Reducing time for virtual commissioning of automated assembly stations through automated testing and more efficient simulation models

- Already at the final review of the project, Daimler had several persons working with the tools from the project, together with even more people at their European suppliers.

- The growth of EKS in the field of digital innovation, from 15 employees (Sep 2013) to 45 employees (Jun 2017) was partly based on their participation in AVANTI.

- TWT advanced the use of co-simulation approaches from its original domain of the automotive development process into several other industry sectors. Of note here are the aerospace industry, the building automation and management sector, and, of course, the field of manufacturing and production planning.

- In terms of standardisation, FMI has started to be integrated into current virtual commissioning systems and there are activities to also integrate it into AutomationML as well as integrating pneumatic plan descriptions into AutomationML.

European industry's need for flexible production system design, optimised time to market and extremely high product quality provided the background for the ITEA 2 project AVANTI. The goal was to develop a virtual commissioning test methodology based on behaviour simulation of production systems to enable leading European OEMs, component and tool providers to gain a competitive edge. The projects two key innovations were: (1) virtualisation of the testing process for industrial production lines and (2) the combination of different models and tools for simulating production to create and perform tests for virtual commissioning and industrial application.

Project results

AVANTI has been at the heart of novel developments in co-simulation or distributed simulation in which the Functional Mock-up Interface (FMI) standard is a common approach. Standardising automation and using functional mock-up interfaces enables better product distribution channels and easy use of standard software, thereby reducing the effort needed to create complex simulation models.

A project result highlight was the collaboration of TWT and EKS InTec to design, specify, implement, and test a co-simulation framework. This framework facilitates co-simulation of mechatronic components of production systems. At its core lies a fast and lightweight FMI-based co-simulation alleviating the integration of co-simulation approaches into existing processes. This performance-based, versatile and scalable simulation approach allows multi-domain simulation based on functional mock-up units, the integration of open or black-box component models, protection of Intellectual Property and easy integration into existing Virtual Commissioning tool chains. Three OEM use cases from different industrial sectors demonstrated the results: Daimler (Germany) in automotive assembly, Arcelik (Turkey) in the production of white goods and Moventas (Finland) for windmill gearbox production and testing.

Exploitation

The AVANTI project generated a set of impressive exploitable results. Daimler, Moventas and Arcelik are using the developed tools in their virtual testing and commissioning process chain. TWT, EKS InTec, and KaTron as participating SMEs are in the process of marketing the developed exploitable results.

Moventas introduced a process simulation tool for gearboxes. They target a virtual prototyping tool to optimise efficiency of the gearbox of wind turbines thereby reducing testing time and optimising energy production.

EKS introduced a virtual commissioning test generation and execution tool for users in the manufacturing sector. This tool automatically generates detailed test cases, performs test cases and provides a detailed overview of the results of test cases performed.

TWT introduced the fast and lightweight co-simulation framework mentioned above to its industrial customers and partners. It supports FMI-based co-simulation, it facilitates integration of simulation approaches into existing process chains, and connects to virtually every modelling and simulation software.

In the white goods manufacturing domain the Turkish partners Arcelik and Katron wanted to reduce the number of stops of trolleys due to collision during line commission. Katron introduced the AVANTI virtual commissioning simulator (AVICS), a tool to provide a generic framework for physics-based 3d simulation.

More information

Download AVANTI impact storyRelated projects

AVANTIOrganisations

Arcelik (Türkiye)Daimler AG (Germany)

EKS InTec GmbH (Germany)

KaTron Defence AeroSpace and Simulation Technologi…

Koc University (Türkiye)

Moventas Gears Oy (Finland)

TWT GmbH Science & Innovation (Germany)