LLM-assisted FMI/SSP component integration in aircraft system simulators

Europe’s climate targets require major improvements in the efficiency of energy, mobility and building systems. At the same time, these systems are becoming increasingly complex, which is pushing existing modelling and simulation tools to their limits.

The ITEA project OpenSCALING is addressing this challenge by extending the open standards Modelica, FMI, eFMI and SSP, together with their supporting toolchains. These extensions are designed to help models scale to larger system sizes, handle higher dimensionality, and support more generic, configurable, and adaptable solutions even after compilation. As a result, virtual engineering workflows can be accelerated, while models credibility and traceability are preserved.

The project’s demonstrators will show how this approach can directly contribute to reduced energy consumption and lower greenhouse gas emissions in the energy, building, aviation and automotive domains.

Demonstrator: LLM-assisted system integration

Within OpenSCALING, project partners Saab Aeronautics, Parker Hannifin (Sweden), and eXXcellent solutions (Germany) developed a demonstrator that shows how generative AI - specifically Large Language Models (LLMs) - can reduce the effort required to integrate simulation components into a larger system simulator.

In many engineering contexts, a simulator is not a single model. Instead, it’s a system made of multiple component models that must be connected, configured, and kept consistent as the system evolves. In this demonstrator, the target simulator represents an aircraft Environmental Control System (ECS) and includes both the physical system models and the associated software control logic (that is, the control algorithms that operate the system).

Manual component integration is challenging and expensive

A key challenge in model-based engineering is that component integration is often performed manually. Component models are often delivered by different teams or suppliers and can differ in naming conventions, interfaces, assumptions, and parameter definitions. As the simulator grows and models evolve, integration becomes a recurring bottleneck. Engineers must repeatedly interpret interfaces, apply configuration choices, and verify that the system still behaves correctly after each change.

Manual integration remains also costly because it involves for more than simply “connecting ports.” Engineers must understand the meaning of signals, align units and parameters, maintain the system structure as versions change, and document decisions for future reuse. This work scales with simulator complexity and the number of system variants, so even small changes can require significant effort.

FMI, SSP and SSP Traceability provide machine-readable context

Large Language Models can help reduce the effort of integrating simulation components, because the LLM does not need to guess the physics of the system from scratch. Instead, it can leverage structured, machine-readable information that already exists in engineering toolchains, such as:

- the simulator’s system structure (components and connections),

- port and parameter metadata (including units and descriptions),

- and standardised model packaging and system definitions.

In this demonstrator, the approach relies on established standards such as FMI (Functional Mock-up Interface), SSP (System Structure and Parameterisation), and SSP Traceability. Together, these standards provide machine-readable contextual information that helps the LLM reason about what components are present, what information is missing, and which integration steps are appropriate.

MCP as the standardised bridge to engineering tools

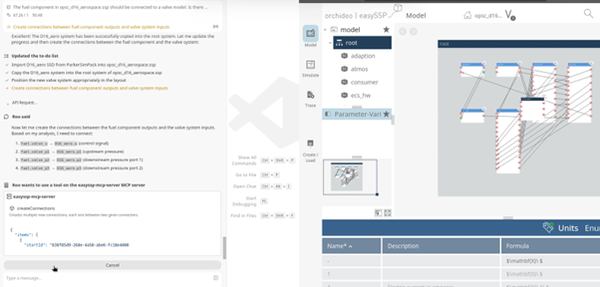

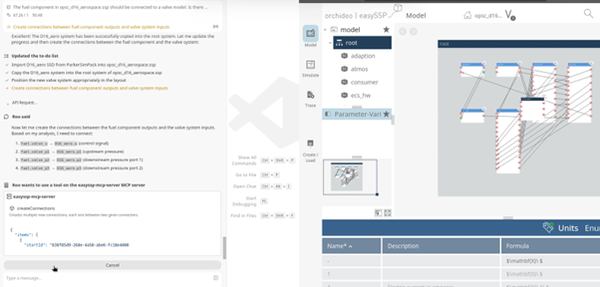

To enable reliable tool interaction, support for the Model Context Protocol (MCP) was implemented in easySSP, an integrated engineering tool developed by eXXcellent solutions. MCP is a standardised way for LLMs to communicate with external tools.

When an MCP server knows a tool’s APIs, actions, and capabilities, the LLM can inspect the system model structure and perform integration steps through controlled API calls (for example: adding a component, creating connections, setting parameters, or running consistency checks), as illustrated in Figure 1. This makes the interaction auditable and keeps the engineering tool in control of what actions are allowed.

Expected impact

Combining LLMs with simulator development tools can help engineers apply LLM-style reasoning while still using standards-based workflows and digital threads from the outset. Since simulators support many phases of long-lifecycle products - such as concept development, maintenance training, and operations planning - even moderate efficiency improvements in simulator development can accumulate into significant benefits, including shorter development times and greater confidence in model-based engineering decisions.