YAZZOOM

From downtime to uptime with real-time anomaly detection

Alexis Piron is Sales Manager at Yazzoom, the AI & Machine Learning company based in the Belgian city of Gent where computer science and engineering are combined to solve many different challenges in all industrial sectors. He takes time out to explain what makes this SME tick.

From undergrowth to clearing

Yazzoom has been around for about eight years. Its beginnings can be traced to 2011 when the company was focused on using data from industry for a whole range of purposes. “It was largely a matter of employing our knowledge of modelling and engineering and matching this to market needs,” Alexis explains, “and in the first few years we tended to undertake projects for companies aimed at using their data to improve the quality of production and products. And using the knowledge and experience we gained in this period, we evolved into developing what is our current product line of data analytics solutions, transitioning from project to product. We cut our way through the undergrowth, if you like, and paved a path towards what we have become today. So yes, we are a company in transition. In fact, we are always in transition – we have to ensure that we stay at the forefront in an environment that changes from day to day so that we can come up with solutions to the constantly evolving challenges.”

Into the unknown

Yazzoom’s application domain solution is more or less the same for all its customers whether in the energy, chemical or automotive sectors. But why do they come to Yazzoom, what is it that makes Yazzoom unique? “A good question,” Alexis replies. “What sets us apart is our ability to combine machine learning and AI with engineering disciplines such as physics, chemistry and advanced process control – this helps to run the results of your machine learning models in the actual production environment. So that’s one thing. Another is our focus on unsupervised machine learning, which is not yet that uses supervised learning, for example."

Cutting away the undergrowth again? “Yes, we are in a much less developed area at this point in time. But it’s a vital matter for our customers because production downtime can be a very expensive situation for them, in terms of revenue losses. This refers to something that happens to disrupt production that is previously unknown or unprecedented. So you’re not prepared for the problems that arise. The traditional methods of monitoring and predictive maintenance are based on the things you know, what has happened in the past. With our unsupervised machine learning, we are clearing the ground to establish something that could be a real benefit to production processes.”

Yanomaly

Alexis is keen to stress the specialised solution Yazzoom has developed for extracting valuable insights and actions from industrial equipment and production line data. “Machines, systems and devices continuously generate data, for example from sensors, that is rich in information about performance, condition, usage and other metrics. Today such data can be collected from fleets of machines or thousands of devices spread over the world and analysing this data can provide valuable insights. However to get to this value is no trivial matter,” he explains.

Publicly funded research projects offer the perfect opportunity to work on solving relevant challenges that none of us can solve on our own.

Yazzoom has built a powerful reusable and extendible technological solution on top of open source technologies combined with proprietary machine learning algorithms. It has some unique capabilities like process mining, the ability to learn automatically from data statistical models that describe how the machines, devices and systems have been used and which process steps were executed by those systems. Then there is context dependent anomaly detection, or the ability to detect in real-time anomalies or abnormal process execution and complex events in both numerical data and log files, while taking into account the context in which the system operates. “Essentially,” Alexis sums up, “Yanomaly’s main use cases are continuous real-time monitoring of assets for operations and maintenance teams of production companies, and faster diagnostics and root cause analysis for service and support teams of equipment manufacturers.”

Benefits of collaboration

Of course, being a small company the need to keep abreast of the latest developments cannot be understated. Publicly funded research projects offer the perfect opportunity, as Managing Director Jan Verhasselt suggests, “to mix with different people and organisations to work on solving relevant challenges that none of us can solve on our own. In R&D, of course, there is always a substantial risk that the ultimate solution will not be found, so such programmes and projects help spread the risk in terms of both effort and funding.” Furthermore," Jan goes on to say, “our main objectives as a technology provider are to get a chance to test and further develop our ideas and technologies on the real use cases provided by the problem owners in projects and, in doing so, to (hopefully) create reference success stories that show the value of our technology.”

Success story

The ITEA project Reflexion is one such success story where technology was developed to generate test suites indistinguishable from real-life user tests, opening up the potential to make systems (and therefore users) safer against threats for which no data currently exists. Ultimately, lower development, maintenance and troubleshooting costs mean a better price-to-quality ratio for customers. Yazzoom is currently involved in iDev40, an EU ECSEL project that is geared to using digital twins for accelerating the time it takes to create new products from development, over planning to manufacturing throughout the value chain. Yazzoom also participates in Flemish R&D programmes like ICON. “An obvious difference here,” Jan explains “is that local Flemish projects typically have smaller partner consortia. Among the European research projects, ITEA requires less work for reporting and the portal is very handy. So for an SME like us, that’s a real bonus.”

More information

https://www.yazzoom.com/

Other chapters

Use the arrows to view more chapters

Editorial

By Jan Jonker

Country focus: Turkey

Creating a climate for impactful R&D

Vice-chairman's blog

by Philippe Letellier

ITEA Success story: OPEES

Open Platform for the Engineering of Embedded Systems

Community Talk with Özgün Algin

Creating innovation, results and exploitation with friends

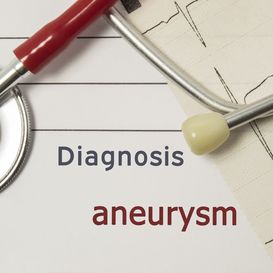

End user happiness BENEFIT

Prevent rupture of a brain artery

ITEA Success story: MODRIO

Digital twins for the safe and efficient design and operation of cyber-physical systems

New ITEA Office Director: Jan Jonker

Right time, right place, right person

SME in the spotlight: Yazzoom

From downtime to uptime with real-time anomaly detection

ITEA PO Days 2019

'Mix between speed dating and a hackaton'

Eureka Stakeholder Conference 2019

Creating ecosystems for innovation