Reflexion

Nourishing high-tech manufacturing with valuable high-quality data

- Project

start

September 2015 - Project

end

February 2019 - Project leader

Bas Huijbrechts

TNO - More

information

itea4.org/project/reflexion.html

The next step forward for the high-tech systems manufacturing domain is to integrate operational data into a product’s development lifecycle. However, as industry increasingly shifts towards complex, digitised systems in which every component generates data, R&D remains largely dependent on legacy engineering choices. Typically, more than 20% of R&D budgets is spent on issues caused by poor quality, sometimes amounting to over 5% of total revenues. Industry executives are thus entering the ‘awareness’ stage: while there is an understanding that data can lead to improved processes, less is understood about the necessary roadmaps to get there. Many companies now operate data pipelines to send information back to headquarters, yet this data is often low quality and delivers no value in generating new business models. Domain-specific knowledge and data science must be combined.

The challenge taken up by the ITEA project Reflexion, comprising eight partners from Belgium and the Netherlands, was to support the paradigm shift emerging in high-tech industry from selling ‘boxes’ to supporting ‘integrated solutions’, by providing significant improvements in quality and stability during early product rollout.

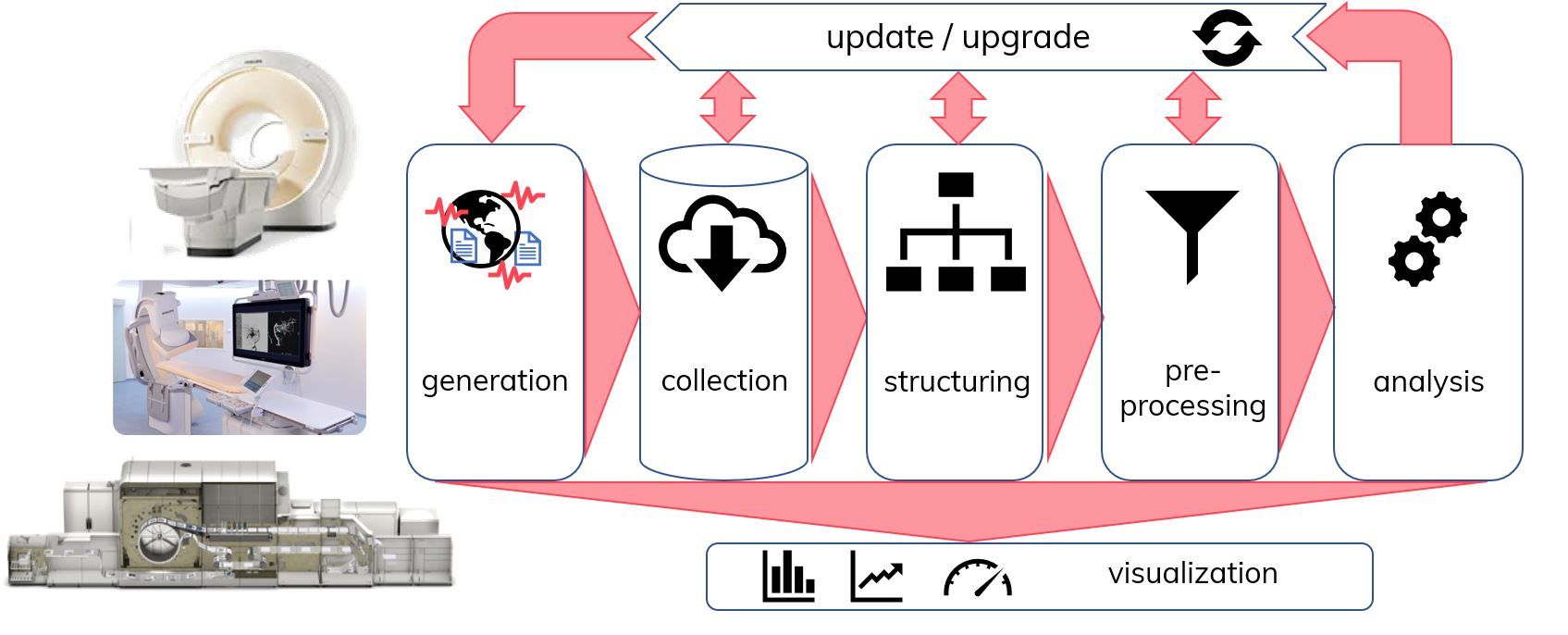

The objectives were defined as follows: to react to unforeseen problems or emerging needs in a fast, cost-effective way by augmenting products with an introspective layer of data sensing and data analytics, thereby creating value out of the high-tech system’s operational data which is still characterised by legacy choices based on infrastructural and analytical approaches. Then propagate this knowledge (automatically) back into the product development lifecycle and the service & maintenance flow.

‘Digital loop’

Reflexion’s success does not lie in a product – a non-existent ‘silver bullet’ to be applied in all circumstances – but in integrating pre-existing frameworks to improve the consortium partners’ processes. There are a wide number of open-source frameworks that specialise in data science, backed by huge communities. Through Reflexion, high-tech systems companies were exposed to these frameworks, helping them to understand what exists and how it can be used to improve their own data management. By augmenting their products with an introspective layer of data sensing and analytics, partners had the opportunity to valorise their operational data and to propagate newfound knowledge back into the development cycle, services and maintenance.

Reflexion introduced another perspective of data exploitation providing a new added value

This creates a so-called ‘digital loop’ in which data is fed back to the ecosystem. Former ITEA Vice-chairman, Philippe Letellier emphasised the importance of this ‘digital loop’: "Unique results are emerging at the very beginning of the industry chain, at the design level. But it is more revolutionary than that. There is no more start or end.”

Thanks to the emergence of cheap sensors and affordable large-scale data storage, terabytes of data are acquired daily from complex systems that are characteristic of the high-tech industry. Whether it is about intelligent equipment in operating rooms, sensors in industrial printing systems or smart energy meters, the trick is to filter the data in such a way that only relevant, valuable information remains that can be used to create overviews and insights. The partners of the Reflexion project have achieved exceptional results in this area and have been rewarded with two awards in 2019 - the ITEA Award of Excellence and a Eureka award.

Tangible profits for manufacturing in terms of time and money

The application of data science in manufacturing was new back in 2015 when data use predominantly targeted the control engineering of mechatronic systems. Reflexion introduced another perspective of data exploitation providing a new added value. Already during the project enormous gains were realised by the project partners as data science was introduced in as yet unexplored domains. As a result, the market penetration for the participating tool and service providers grew by 10% in terms of both improved product offering and extended services.

The Dutch SME Axini has further developed and improved its platform for scriptless test automation. The unique property of the Axini approach is that programmers, who are few and far between, do not need to program test cases and test data. Instead, AI and formal method algorithms automate the entire test process: test case generation, execution and evaluation. As an achievement resulting from Reflexion, Axini refined and optimised its platform for calculation engines, for example as used in pension and insurance calculations. Axini has productised the project’s prototypes into its platform and has proven that the new approach is 50% faster and more effective than all other alternatives in the market. Thanks to these achievements, Axini aims to realise an additional € 2.5 m of revenue between 2020-2025 and company growth of 20%. The Belgian SME Yazzoom has further developed and improved the algorithms in its Yanomaly software for anomaly detection and predictive analytics on machine data. In particular, algorithms were created and validated for semi-automatic parsing and anomaly detection in log files. Aside from the visibility and reference cases offered by its participation in Reflexion, Yazzoom expects that the results of the Reflexion project will lead to an additional revenue of €2.5 m in the five years after the project.

As a result, the market penetration for the participating tool and service providers grew by 10%

The Dutch SME SynerScope undertook, amongst others, a Stedin Smart Meter customer case, since difficulties existed in planning maintenance staff to replace meters because not all data was readily available. The tabular data contained gaps, making it difficult to send the right person to the right household. Bridging the existing tabular data with log, text and image data allowed SynerScope to bring the first-time-right percentage up from 90% to 99.5%, saving an effective 40 FTE. In general, SynerScope saw a 30% reduction in time spent troubleshooting performance issues at the customer site by using structured log analysis and analytics on interaction logs. This is now part of its user experience monitoring, reducing the time from initial problem to pinpointed bottleneck at least by half. In addition, the structured log analysis has opened up exploitation in new verticals Energy and Oil & Gas, which represents a multimillion-euro market opportunity.

Additionally, for the OEMs the impact of Reflexion on the growth in turnover and / or market penetration for selected applications was projected at 20%.

On a more concrete level, Canon Production Printing (formerly known as Océ) did agile development with its launching customers for its new inkjet printer, the VarioPrint i300. To determine the actual specification of the new product, the daily 4GB of data produced by the printer’s 300 sensors and 150 actuators was exploited with the development of an Optimal Diagnosis Analysis System (ODAS). Beyond automatic analysis, the key was to support quick knowledge sharing between the company’s different specialists to reach a common understanding of the situation and decide together on what to enhance. To support its teams, Canon Production Printing generalised the usage of the open source Jupyter Notebooks which easily enables information, models and code to be mixed, allowing all the engineers - not only the software experts - to express their viewpoints. For example, when confronted with an alarm coming from the automatic usage data analysis, designers from different disciplines can quickly share their analysis and together propose a solution that can be realised through an agile approach. During Reflexion, Canon Production Printing developed an incredible maturity on this full digital loop and a set of products and methodologies that can be useful for many other European players. Thanks to this new approach, Canon Production Printing has improved its mean time to repair (MTTR) for all new machines by 50%.

Philips and Barco improved products with a significant impact on wider society. By exploiting data more efficiently, for instance, both can now create medical equipment with a higher uptime, meaning the possibility to diagnose or operate on more patients per day. In addition, thanks to Reflexion, Philips partnered up with Yazzoom for further research resulting in the development of a platform for both further research and new services. For Barco and TNO, new business models (e.g. the NEXXIS Care Plan) were introduced, the value of which at the end of the project in 2019 was estimated at 20 million euros in the next 5 years.

Siemens Industry Software has made its first steps into machine learning during the project. It resulted in the development of the new Simcenter Studio tool released in 2021 as a completely new solution in the Simcenter portfolio. The methods of the new tool have been in commercial use for several years already in the automotive, aerospace, and other industries. Primary use has been in the context of Generative Engineering assisting the preliminary design of systems. Support of machine learning in design workflows, which are continuously being extended through running R&D projects, is one of its important features. As proven in Reflexion, the tool offers excellent integration with behavioural simulation tools to train machine learning algorithms in a simulation-driven way.

A winner ahead of the game

Apart from the incredible industrial impact, already during the project 25 data science jobs were created among the project partners. This workforce is continuing to work on the Reflexion agenda and address several Smart industry challenges such as effective use of scarce human expert capital by exploiting data to assist the realisation of better operational solutions and designed systems.

For all partners Reflexion turned out to be genuine successful collaboration. Ronald Begeer, involved from the beginning in Reflexion on behalf of ITEA, summarises this nicely: “As mentor of the Reflexion project I am proud of the results achieved by the partners in the project. Due to the fact that only two countries received funding the Reflexion project had a challenging start in defining the goals of the project. The ESI (TNO) project leader managed to align the partners well and achieved excellent results, creating an impressive impact on digitalisation and tool development for big data analysis. Especially new market opportunities for the industrial partners and SMEs were recognised by the ITEA organisation, which made the Reflexion project a justified ITEA and Eureka award winner.”

More information

Download Reflexion Success storyRelated projects

ReflexionOrganisations

Axini (The Netherlands)Barco N.V. (Belgium)

Canon Production Printing Netherlands B.V. (The Ne…

Dataseen BV (The Netherlands)

Philips Electronics Nederland BV (The Netherlands)

Siemens Industry Software NV (Belgium)

TNO (The Netherlands)

Yazzoom (Belgium)